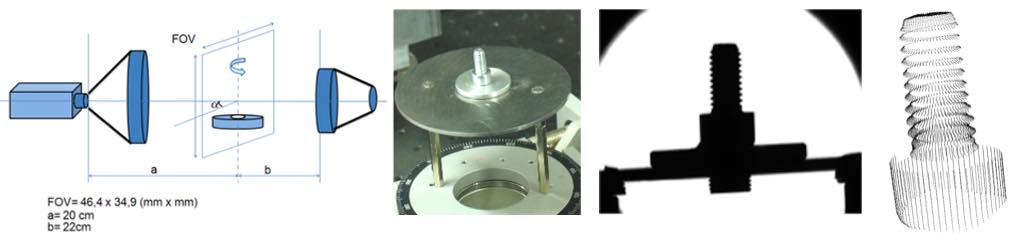

The aim of this project is to develop and test novel image processing algorithms for image deconvolution and analysis specifically designed for real time, hardware-independent operations. The final goal is to share the image analysis capabilities using cloud computing techniques, by means of a specifically developed web-based system.

This project involves a lasting collaboration between the faculty of Engineering at Università degli Studi di Brescia and the Mechanical Engineering department at MIT. It is supported by the CARIPLO UniBS-MIT-MechE project, a faculty exchange program agreement designed to promote new long term scientific collaborations and to consolidate existing collaborations between faculty members of UniBS and MIT-MechE.

The faculties involved into this program are Prof. Giovanna Sansoni, for the University of Brescia, and Prof. Forbes Dewey, for the Massachusetts Institute of Technology.

As part of project, Prof. Sansoni of the University of Brescia visited MIT for three months in the early Fall of 2011 to inaugurate the personal exchange program. Prof. Sansoni gave a lecture at MIT, entitled “3D imaging and surroundings“.

During her stay at MIT, she had the opportunity to meet a number of Prof. Dewey’s collegues. Among them, Prof. George Barbastiathis gave a number of useful suggestions on non-linear image analysis approaches. The exchange she had at MIT made it possible to establish the basics for an extremely stimulating research field, dealing with image denoising, deconvolution and compression to be performed across the web.

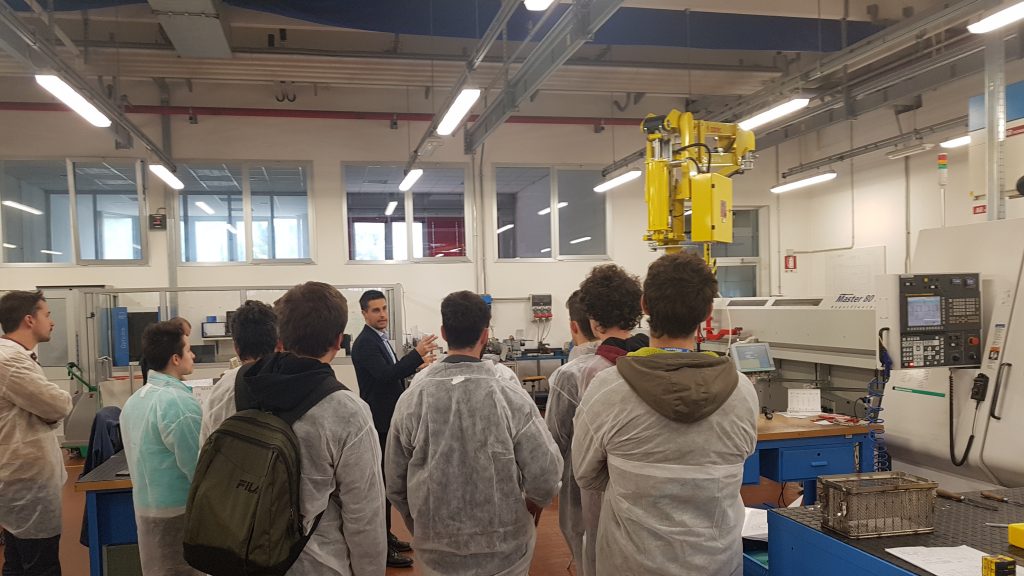

Prof. Dewey travelled to Brescia for two weeks in April of 2012. The aim of his visit was twofold: on one hand, he interacted with Prof. Sansoni Laboratory to optimize the collaboration. He also met people from the Laboratory Start-Ups, and realized how rich and powerful is the high-technology pole generated by the Laboratory.

On the other hand, he gave two seminars open to Ph. D. students and researchers of the University of Brescia. In the first seminar, entitled “Quantitative Models of Cellular Biology: Application to Cellular Dynamics and Drug Development“, he gave two examples of how one can begin to put large-scale quantitative biological models together to predict ab into the results of altering drug dosages and creating drug combinations. In the second seminar, enitled “Super-Resolution Optical Microscopy: Beating Photons at Their Own Game“, he addressed the application of measuring the mechanical properties of living cells using 3D stacks from optical microscope images, far beyond the Rayleigh criteria.