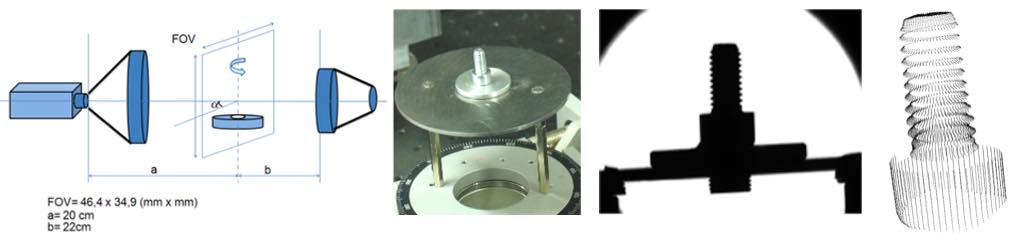

The objective of this project was to develop a vision system for the real-time acquisition and saving of images produced in laser welding processes. This activity represents an initial step in the context of a research project aimed at studying the relation among the welding parameters and the quality of the welds, as they are captured by the vision system, for the feedback of the welding parameters during the welding.

The Laboratory worked in collaboration with TubeTech Machinery srl (Cazzago San Martino, Brescia, Italy), that was the company interested into this study.

The hardware used to devop this application is the Embedded Vision System (National Instruments) with LabVIEW 8.6.1, the IMAQ Vision libraries and the Real Time module for LabView. The vision system is based on the cooperation between a Host PC (PCS), and the NI EVS 1464 device. The acquisition campaigns have been done on one of the welding machines available at TubeTech Machinery.

Suitable image elaboration tools have been developed to extract information from the videos captured by the system.