HANDS-FREE V2

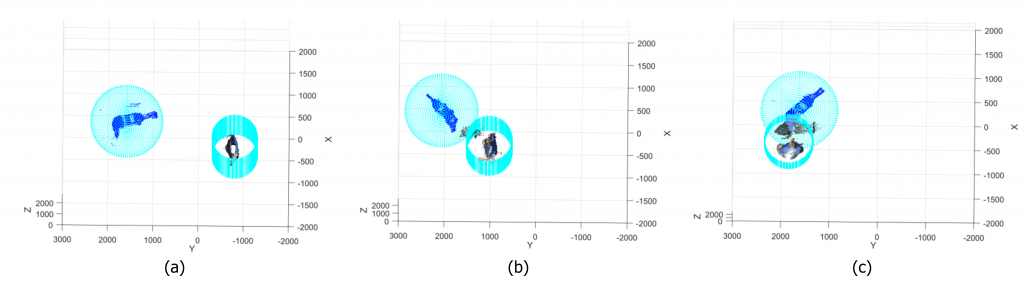

The idea of this thesis project is to improve the already developed teleoperation system presented at Ubiquitous Robotics by implementing the z-axis control. In fact, the original system only performed a xy teleoperation allowing users to move the end-effector of the robot to the desired position determined by the index finger keypoint extracted by OpenPose. However, a more interesting application also integrates a precise z-axis control and a trajectory planner, which are the key improvements of this version as seen in Fig. 1.

SETTING UP THE SYSTEM

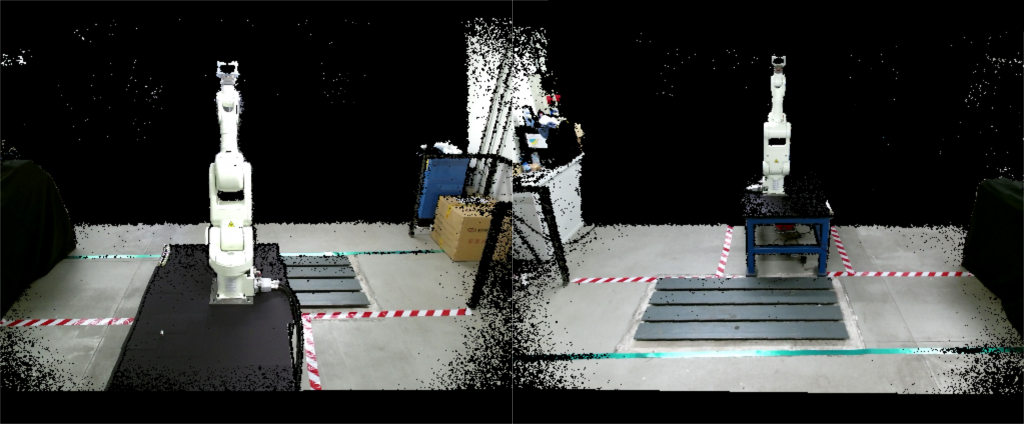

Due to the COVID-19 pandemic restrictions, this project has been carried out using ROS Gazebo to reproduce the laboratory set-up already seen for Hands-Free v1. The camera adopted is a consumer-end RGB camera that has been calibrated following the standard procedure described in Hands-Free v1 paper. The robot calibration has been similarly performed by setting up a simulated environment as shown in Fig. 2.

BUILDING THE TRAJECTORY

The trajectory builder is an extension of the capabilities of the old version of the software, hence it only works in 2D considering the user frame (xy plane) and the vertical robot frame (zy plane). The procedure to use this application is the following and may be seen in the video below:

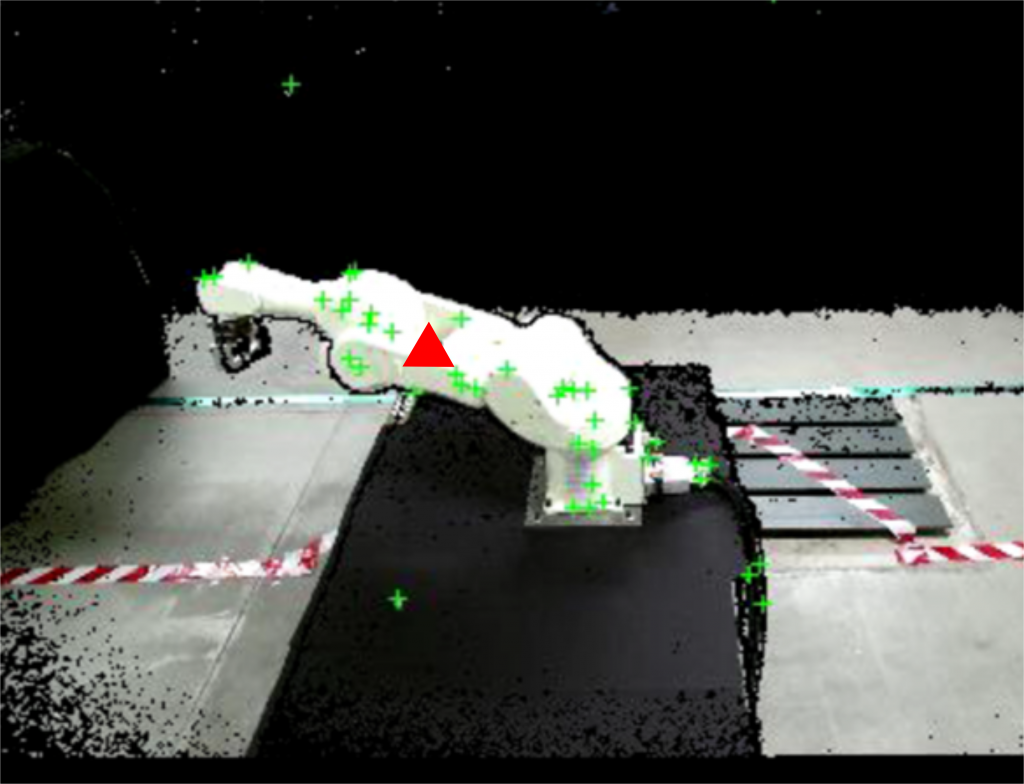

- Users place their hand open on the user frame in order to detect the “hand-open” gesture. This allows the system to reset the variables and move the robot to its home pose (Fig. 3)

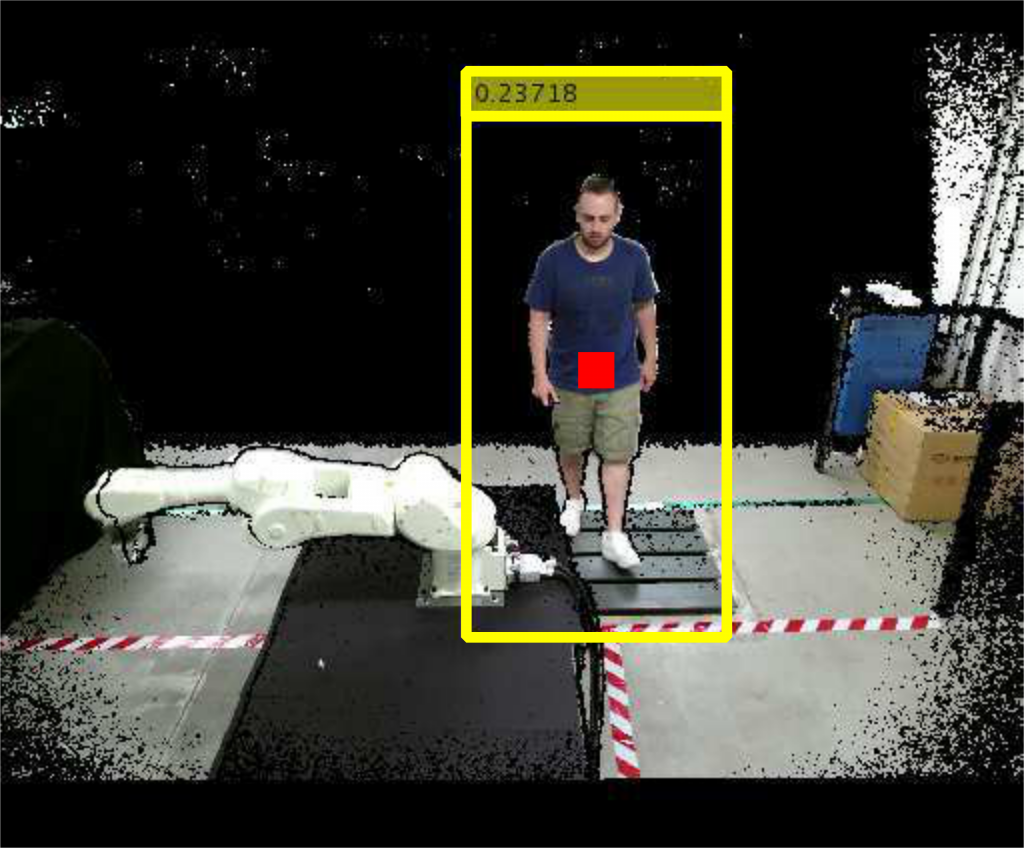

- After the initialization phase, users may move their hand around the user frame performing the “index” gesture (with both thumb and index finger opened). The index finger position is extracted considering keypoint 8. Only positions which differ from the preceding one of at least 5 px are retained. Moreover, each position is extracted as the mean position detected over N consecutive frames. In this case, we set N = 3 (Fig. 4)

- The detected trajectory points are filtered and interpolated according to the ad-hoc interpolator developed. The resulting trajectory may be sent to the robot if the “move” gesture is performed (with index and middle fingers opened, see Fig. 5).

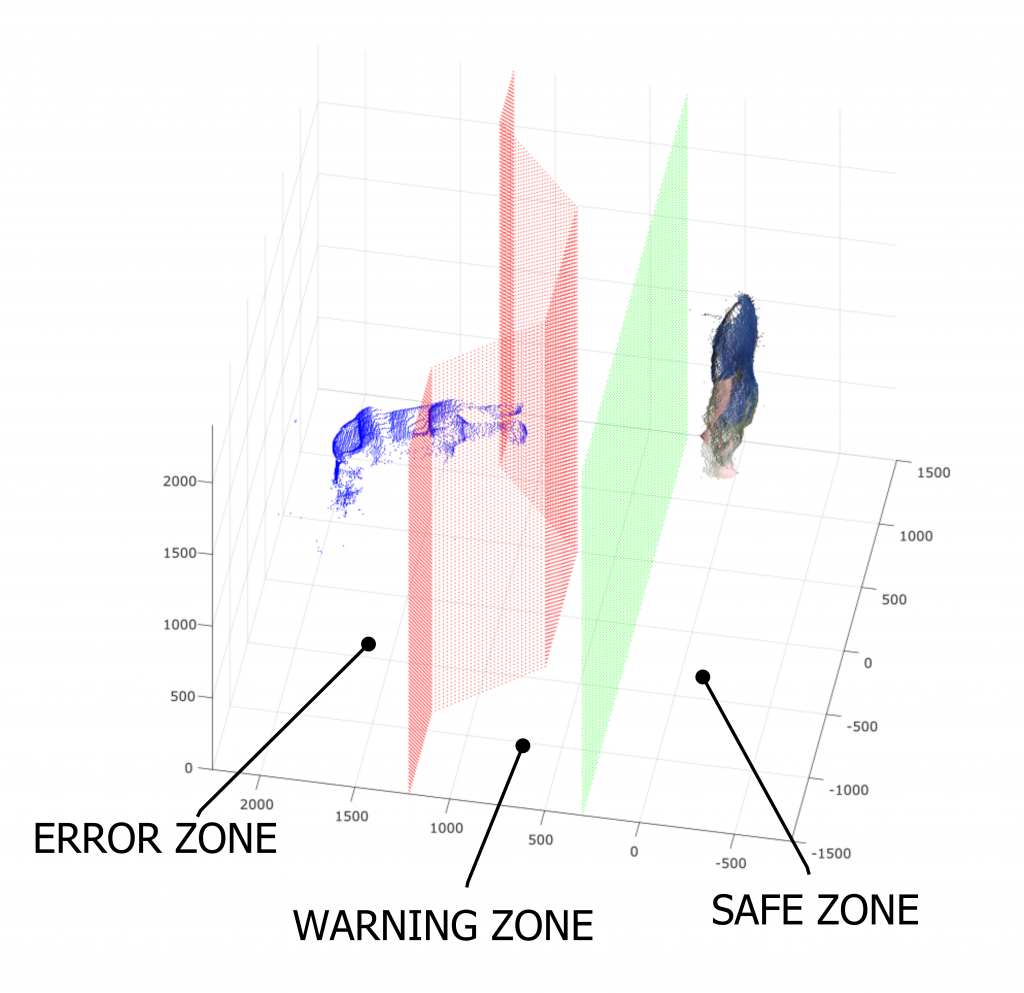

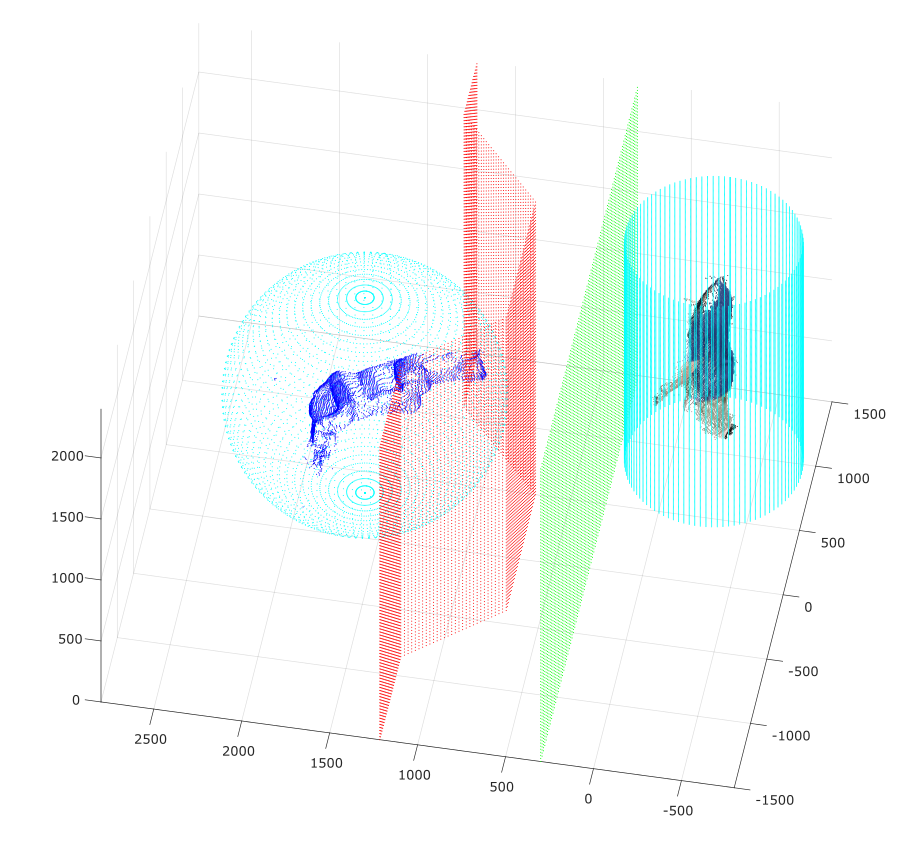

Z-AXIS CONTROL

To control the manipulator along the z-axis (which in this set-up corresponds to the robot’s x-axis) three different modalities have been studied and implemented. For now, however, the depth control is still separate from the trajectory planner.

KEYBOARD

FINGERS DISTANCE

KAI SENSOR

The last modality implements depth control by leveraging the Vicara Kai wearable sensor. The sensor should be wear on the hand and, according to the detected orientation of the opened hand, it is possible to determine if the robot should stay still (hand parallel to the ground), move forward (hand tilted down), or backward (hand tilted up).

RELATED PUBLICATION

C. Nuzzi, S. Ghidini, R. Pagani, S. Pasinetti, G. Coffetti and G. Sansoni, “Hands-Free: a robot augmented reality teleoperation system,” 2020 17th International Conference on Ubiquitous Robots (UR), Kyoto, Japan, 2020, pp. 617-624, doi: 10.1109/UR49135.2020.9144841.