Recently, the integration of vision with robots has gained considerable attention from industry. Pick and place, sorting, assembling, cutting and welding processes are examples of applications which can have great advantage from the combination of information from 3D images with robot motion.

Our laboratory developed, in collaboration with DENSO EUROPE B. V., a system integrating 3D vision into robotic cells. The project led to the Roboscan system.

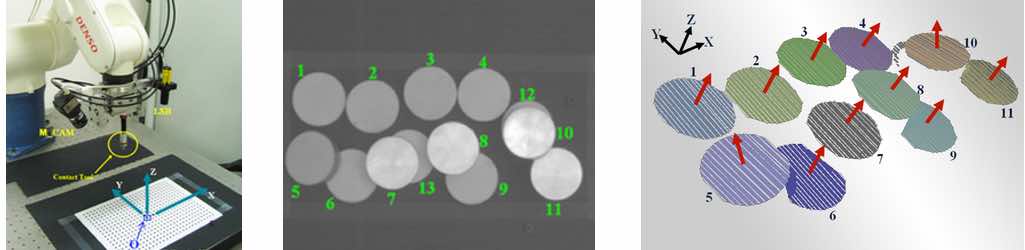

Roboscan is a Robot cell that combines 2D and 3D vision in a simple device, to aid a Robot manipulator in pick-and-place operations in a fast and accurate way. The optical head of Roboscan combines the two vision systems: the camera is used “stand-alone” in the 2D system, and combined to a laser slit projector in the 3D system, which operates in the triangulation mode. The 2D system, using suitable libraries, provides the preliminary 2D information to the 3D system to perform in a very fast, flexible and robust way the point cloud segmentation and fitting. The most innovative part of the system is represented by the use of robust 2D geometric template matching as a means to classify 3D objects. In this way, we avoid time-consuming 3D point cloud segmentation and 3D object classification, using 3D data only for estimating pose and orientation of the robot gripper. In addition, a novel approach to the template definition in the 2D geometric template matching is proposed, where the influence of surface reflectance and colour of the objects over the definition of the template geometry is minimized.

Related Publications

Bellandi, P.; Docchio, F.; Sansoni, G. “Roboscan: a combined 2D and 3D vision system for improved speed and flexibility in pick-and-place operation“, The International Journal of Advanced Manufacturing Technology, Vol. 69, no. 5–8, pp. 1873–1886. 2013