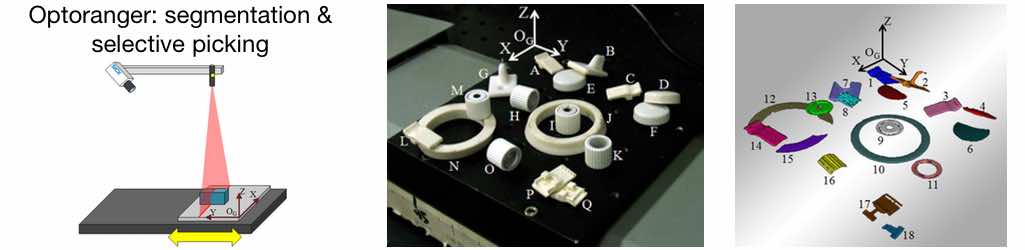

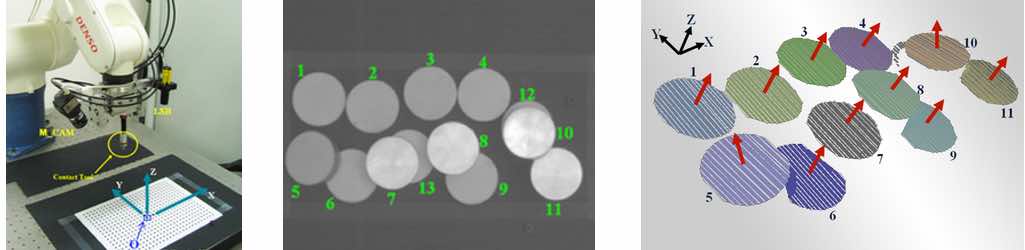

Optoranger is a new method, based on 3D vision, for the recognition of free-form objects in the presence of clutters and occlusions, ideal for robotic bin picking tasks. The method can be considered as a compromise between complexity and effectiveness.

A 3D point cloud representing the scene is generated by a triangulation-based scanning system, where a fast camera acquires a blade projected by a laser source. Image segmentation is based on 2D images, and on the estimation of the distances between point pairs, to search for empty areas. Object recognition is performed using commercial software libraries integrated with custom-developed segmentation algorithms, and a database of model clouds created by means of the same scanning system.

Experiments carried out to verify the performance of the method have been designed by randomly placing objects of different types in the Robot work area. The results demonstrate the excellent ability of the system to perform the bin picking procedure, and the reliability of the method proposed for automatic recognition of identity, position and orientation of the objects.

Related Publications

Sansoni, G.; Bellandi, P.; Leoni, F.; Docchio, F. “Optoranger: A 3D pattern matching method for bin picking applications“, Optics and Lasers in Engineering, Vol. 54, pp. 222-231. 2014