The work performed on the Ferrari presents a number of similarities with respect to the work performed on the Winged Victory: it included the 3D optical digitization of the car, and the generation of a number of polygonal and CAD models.

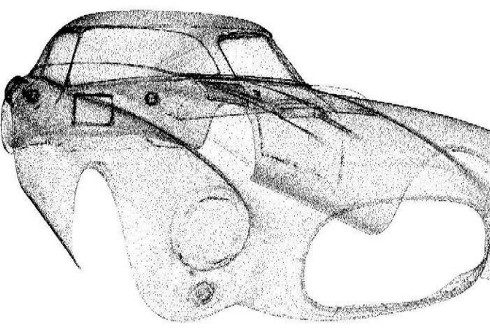

Fig. 1 shows a view of the whole point cloud obtained by aligning and merging 280 partial point clouds. The step has been performed with the help of suitable markers placed on the surface, given the dramatic regularity of the shapes, and the need to keep the alignment error as lower as possible. Moreover, a skeleton of few, large views (550 x 480 mm), with height resolution of 0.2 mm and measurement variability of 0.1 mm has been obtained in the first step. Then, smaller views (370 x 300 mm), with resolution of 0.1 mm and measurement error of 0.06 mm, have been acquired and merged together using the skeleton as the reference.

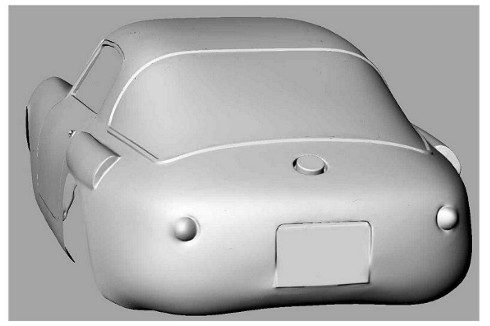

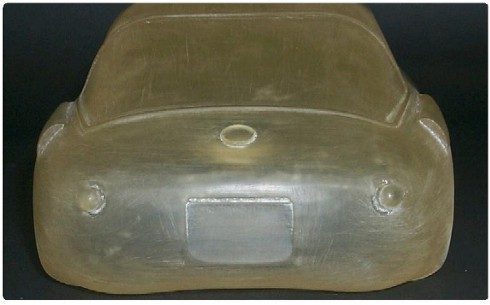

As the last step, the CAD model has been created starting from the triangle mesh of Fig. 2, with minimum intervention of the operator. Fig. 4 shows the rendering of this model (the IGES format is used, resulting in a 120 MB file). The prototype of the car has been obtained at the Laboratory of Fast Prototyping of the University of Udine. The process involved the stereo lithography technique. Similarly to the prototyping of the head of the Winged Victory it resulted into the 1:10 scaled reproduction shown in Fig. 5.